BALANCING ROTORS.

ELIMINATING VIBRATION.

BOOSTING PERFORMANCE.

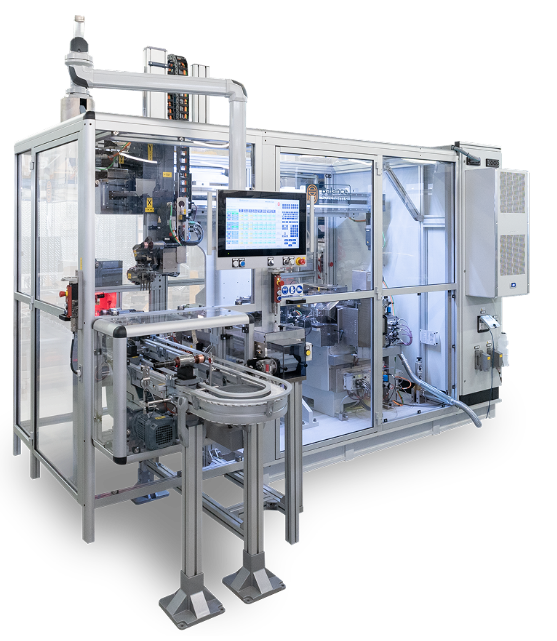

Balancing machines are high-tech solutions designed to eliminate vibrations in rotating parts of electrical, mechanical, and electromechanical systems. These vibrations and the resulting noise are typically caused by unbalance. By dynamically balancing each rotor during production, these machines enhance performance, extend component lifespan, and ensure smoother operation.

Our balancing machines: tailored to your needs.

Our balancing machines come in automatic, semi-automatic, and manual versions. The unbalance correction method varies depending on the type of rotor to be balanced, allowing us to tailor solutions precisely to each customer’s specific needs and applications.

YOUR ROTORS. OUR SOLUTIONS.

FANS AND

ELECTRIC FANS

DISCOVER PRODUCTS

WOUNDED

ARMATURES

DISCOVER PRODUCTS

BELLS

ROTORS

DISCOVER PRODUCTS

WASHING MACHINE

ROTORS

DISCOVER PRODUCTS

GENERAL

PURPOSE

DISCOVER PRODUCTS

VACUUM CLEANER

MOTORS

DISCOVER PRODUCTS

E-DRIVES AND

SIMILAR Rotors

DISCOVER PRODUCTS

SPECIAL

APPLICATIONS

DISCOVER PRODUCTS

BALANCING: WHY IT REALLY MATTERS? + -

Balancing is essential to performance, safety, and product quality. Imbalance in rotating parts causes vibrations, noise, faster wear of components, and reduced operating life. It can loosen bolts, damage electronics, lower precision, and make machines less competitive. Whether it’s a noisy power tool or a vibrating car, imbalance undermines reliability and user experience. Precision balancing eliminates these issues—extending lifespan, improving efficiency, ensuring safety, and enhancing product value. In short: if it rotates, it must be balanced.

ROTORS: WHICH COMPONENTS NEED TO BE BALANCED? + -

Balancing is essential for any rotating component because even slight unbalance can cause excessive vibration, noise, premature wear, and energy loss. These effects not only reduce the efficiency and lifespan of the machinery but can also compromise safety and product quality. From the automotive sector to aerospace, from household appliances to industrial and manufacturing equipment, rotating components are everywhere—and they all require proper balancing to ensure smooth, reliable, and precise operation. Wherever rotation is involved, balancing becomes a key factor in achieving performance, durability, and competitiveness.

INDUSTRIES.

We design and manufacture balancing machines tailored to a wide range of industries — including automotive, aerospace, textiles, home appliances, civil engineering, machine tools, and electric motors. Each solution is engineered to meet the specific requirements of the application, delivering precision, reliability, and high performance to ensure consistent results across every sector.

COMPONENTS.

We offer advanced solutions for a wide range of rotating components. Our systems are designed to balance parts such as power tool accessories, brake discs, clutches, textile spindles, cardan shafts, armatures, blades, grinding wheels, electric motors, impellers, pumps, pulleys, rotors, drums, turbines, and fans — ensuring optimal performance, durability, and efficiency in every application.

GET IN TOUCH

HERE TO LISTEN.

TO FIND THE SOLUTION.

TOGETHER.

*mandatory fields