General purpose rotors are used across a wide range of industrial applications. Regardless of the sector, unbalance in these rotating components can cause excessive vibration, increased noise, reduced efficiency, premature wear of bearings and mechanical parts, and ultimately, equipment failure.

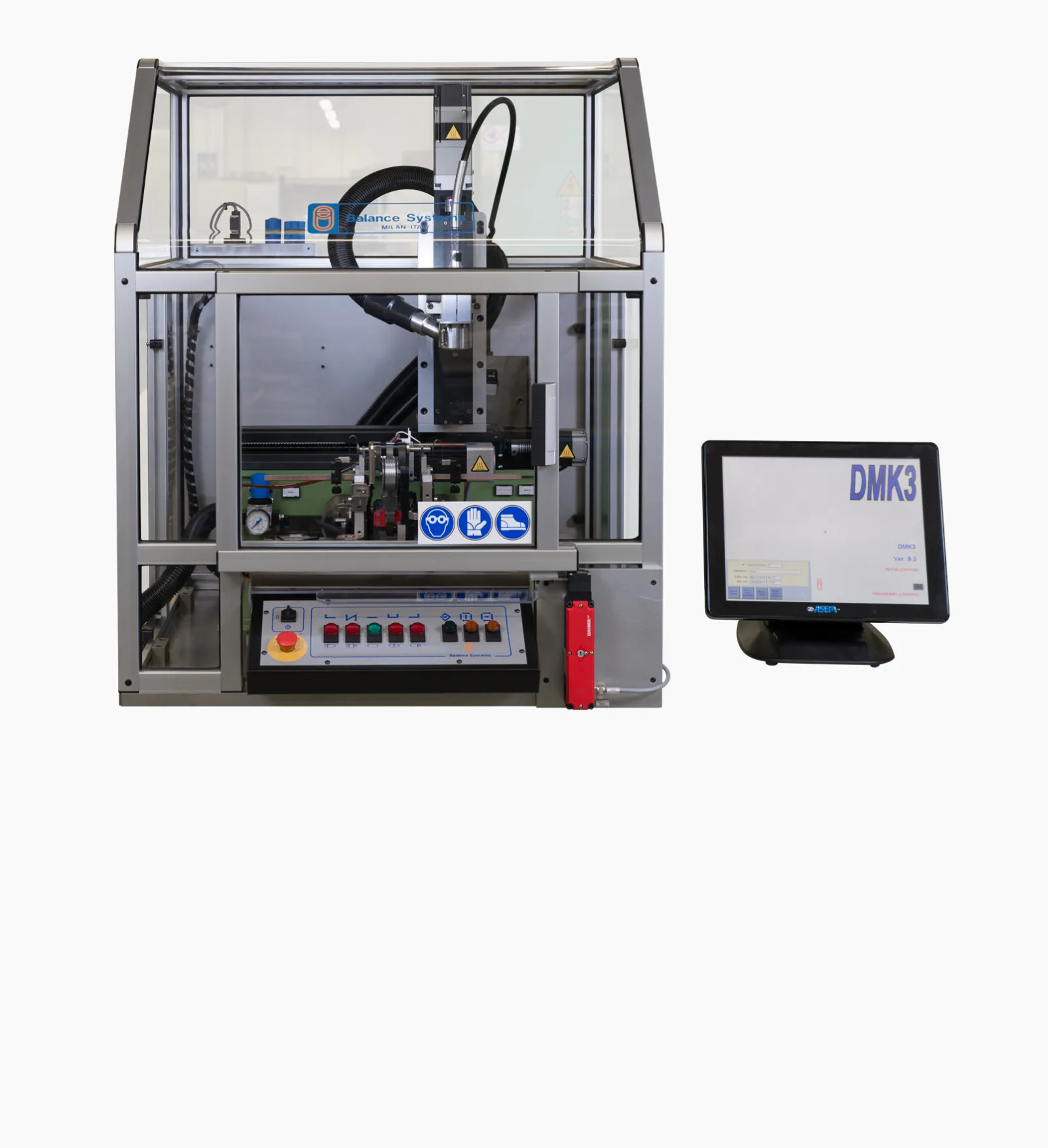

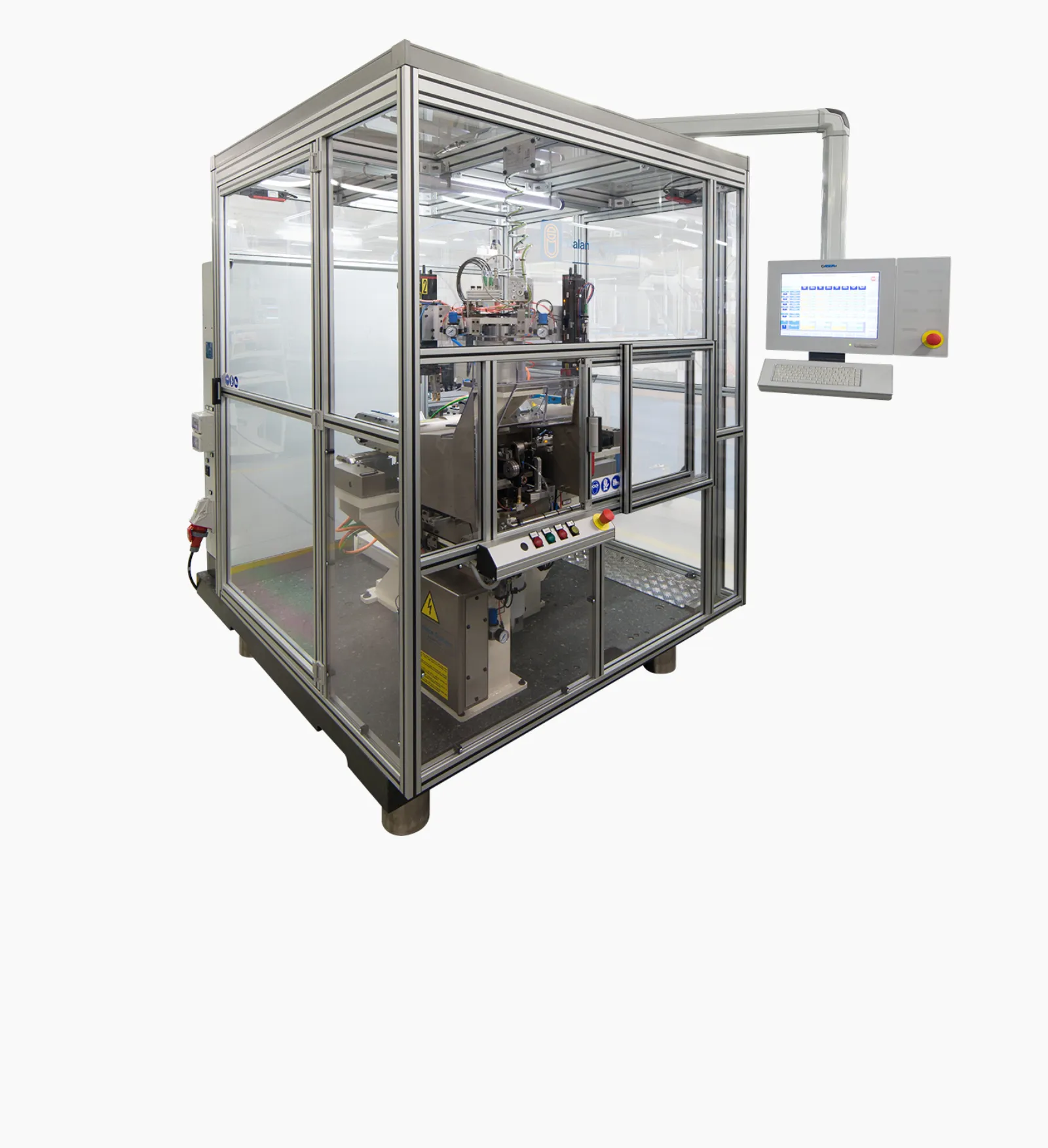

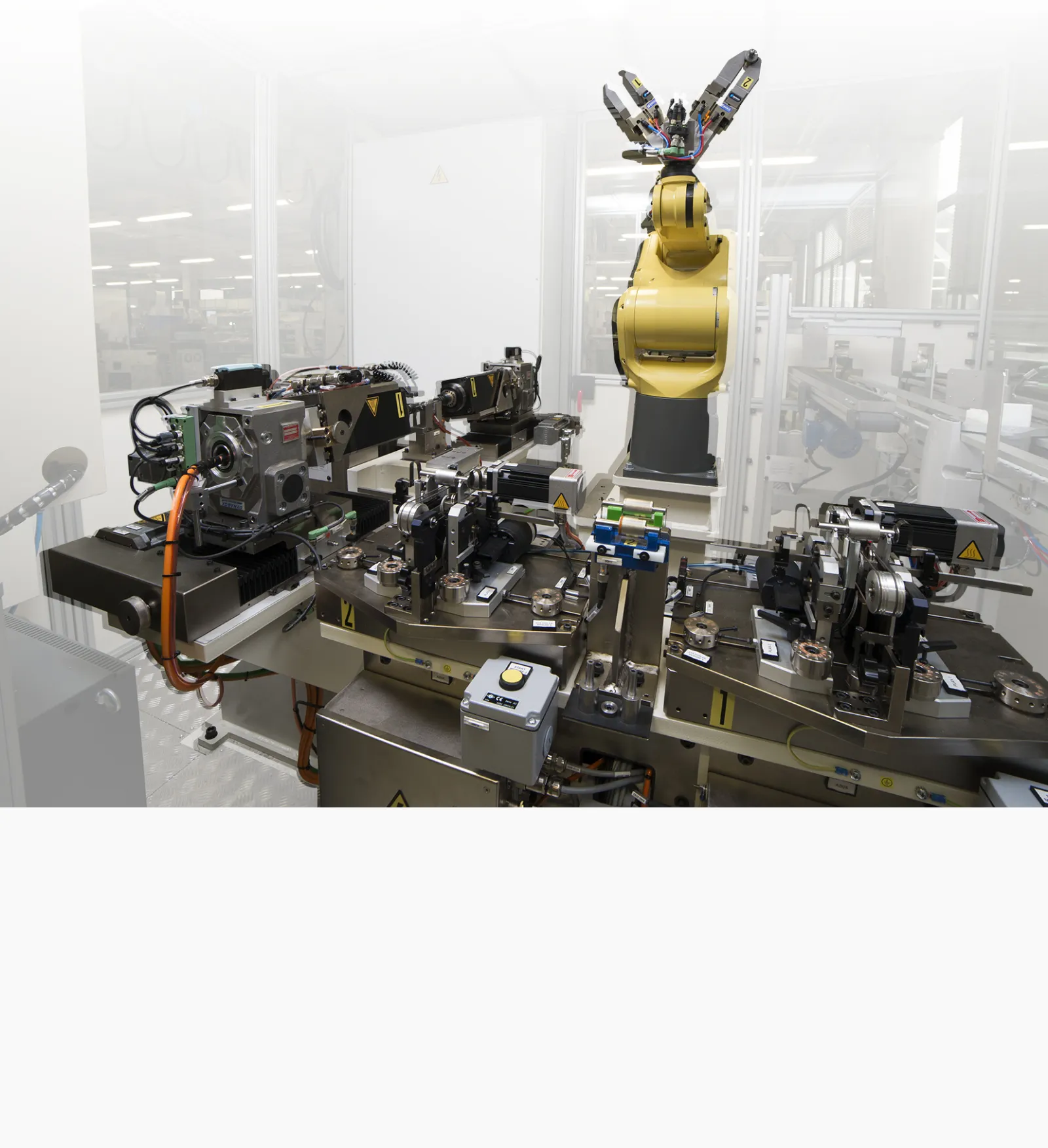

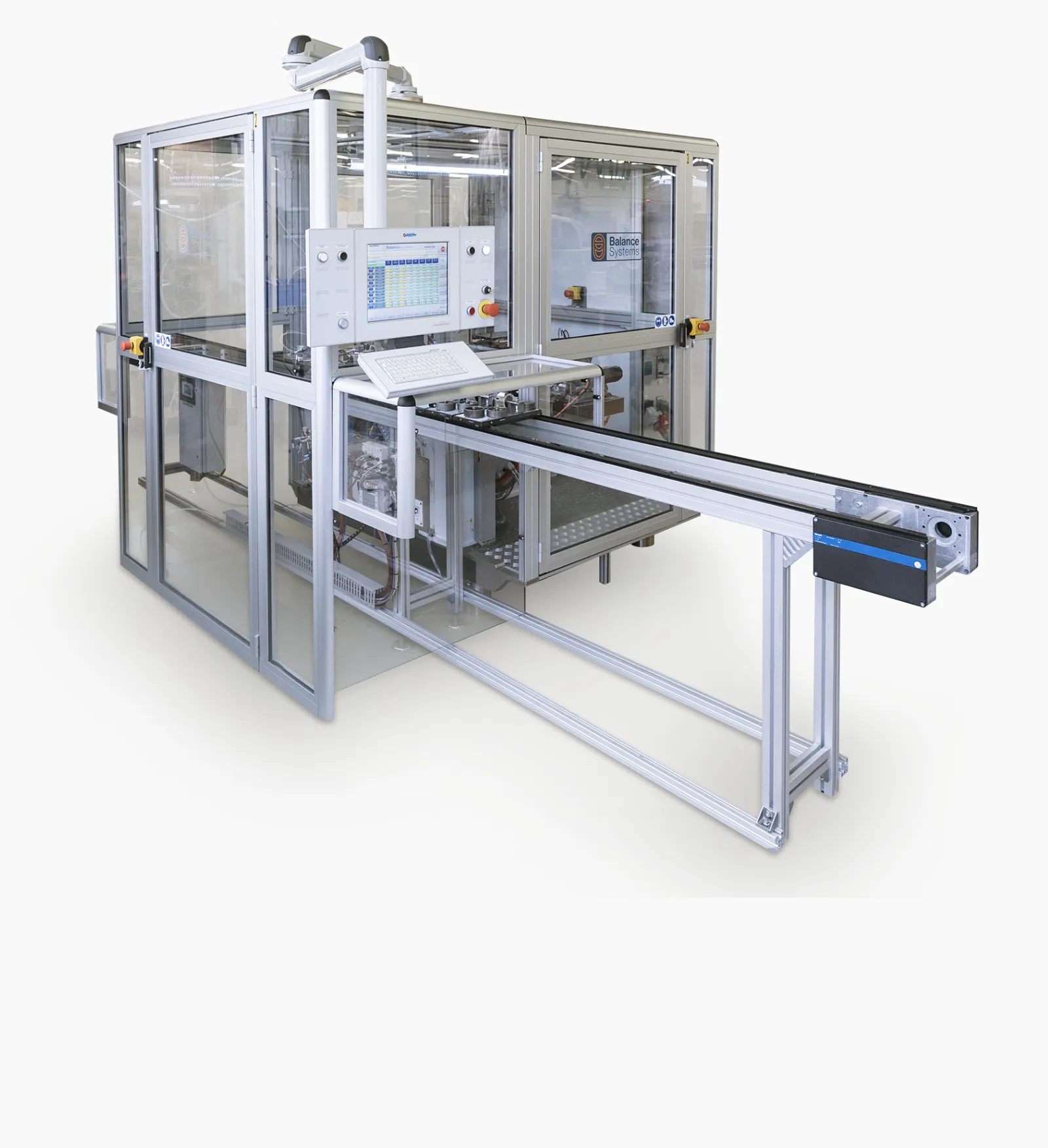

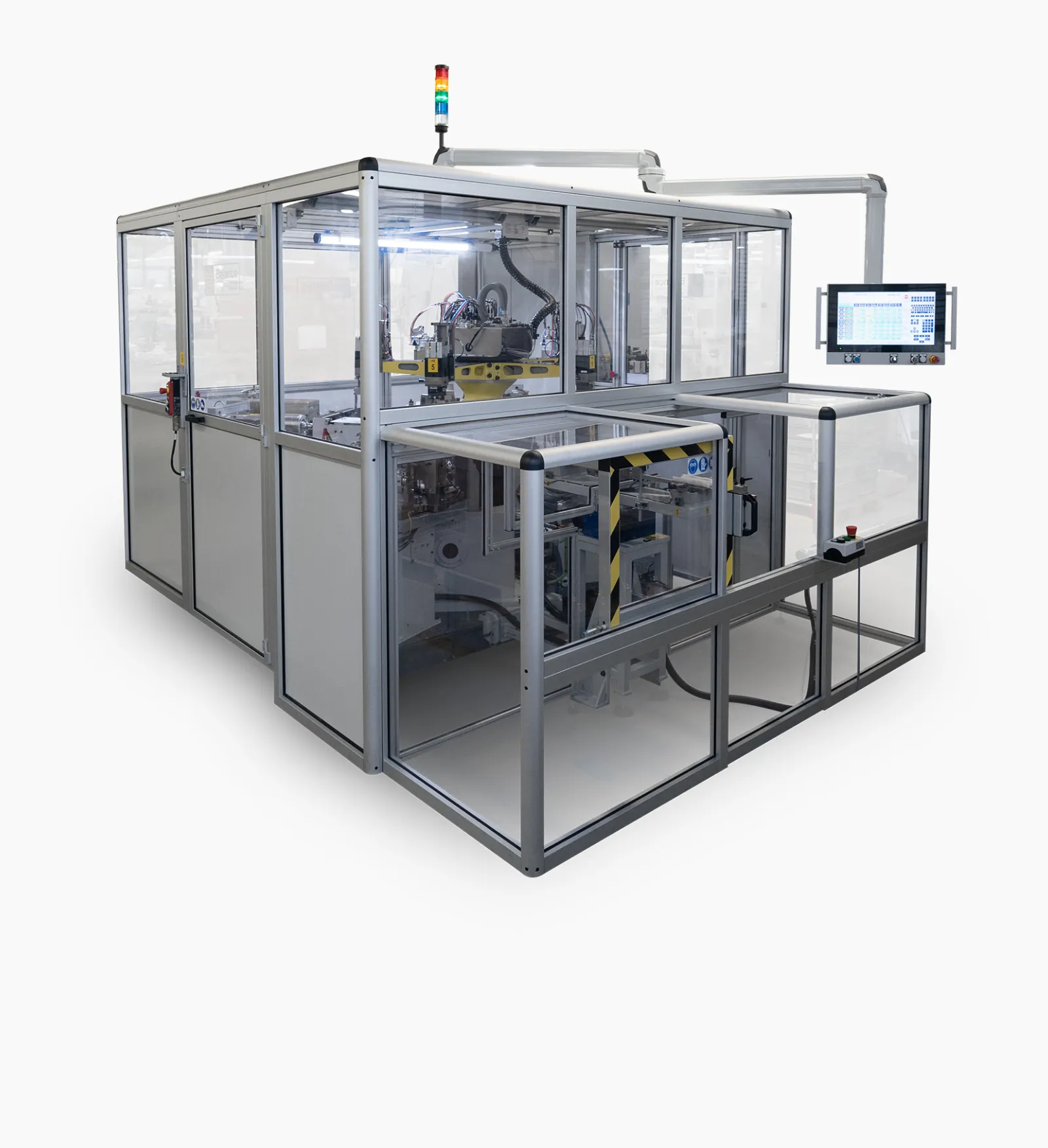

Balance Systems provides high-precision balancing machines - manual, semi-automatic, and fully automatic - engineered to meet the diverse requirements of general purpose balancing. Our machines utilize advanced force-measurement technology to detect unbalance and correct it through drilling, milling, or mass addition, depending on the rotor's geometry and operational constraints.

Proper rotor balancing ensures smooth operation, extends component lifespan, reduces maintenance costs, and preserves overall system performance. With cutting-edge electronics, user-friendly software, and highly configurable designs, Balance Systems delivers reliable, tailored solutions for every production environment.

OUR BALANCING MACHINES.

DESIGNED FOR YOUR NEEDS.

TAILORED TO YOUR ROTORS.

GET IN TOUCH

HERE TO LISTEN.

TO FIND THE SOLUTION.

TOGETHER.

*mandatory fields